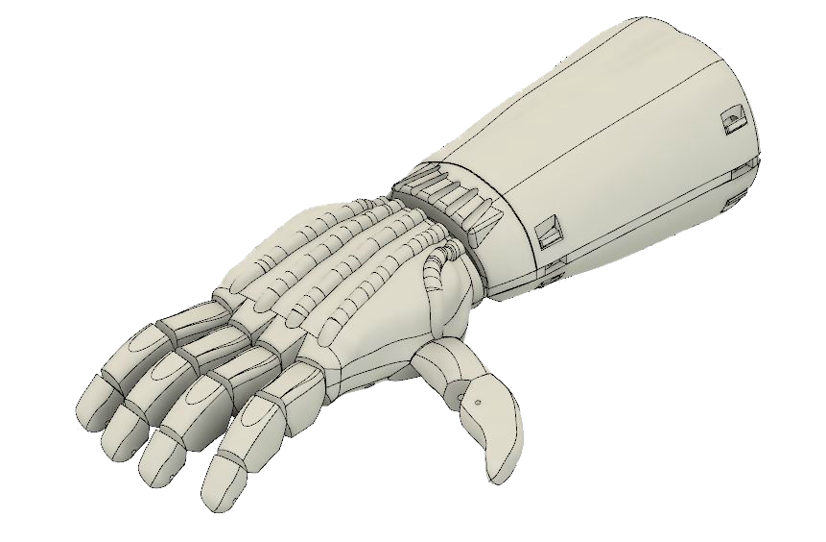

AIO Prosthetic Hand

Interested in building one for yourself? There’s an Instructables Page!

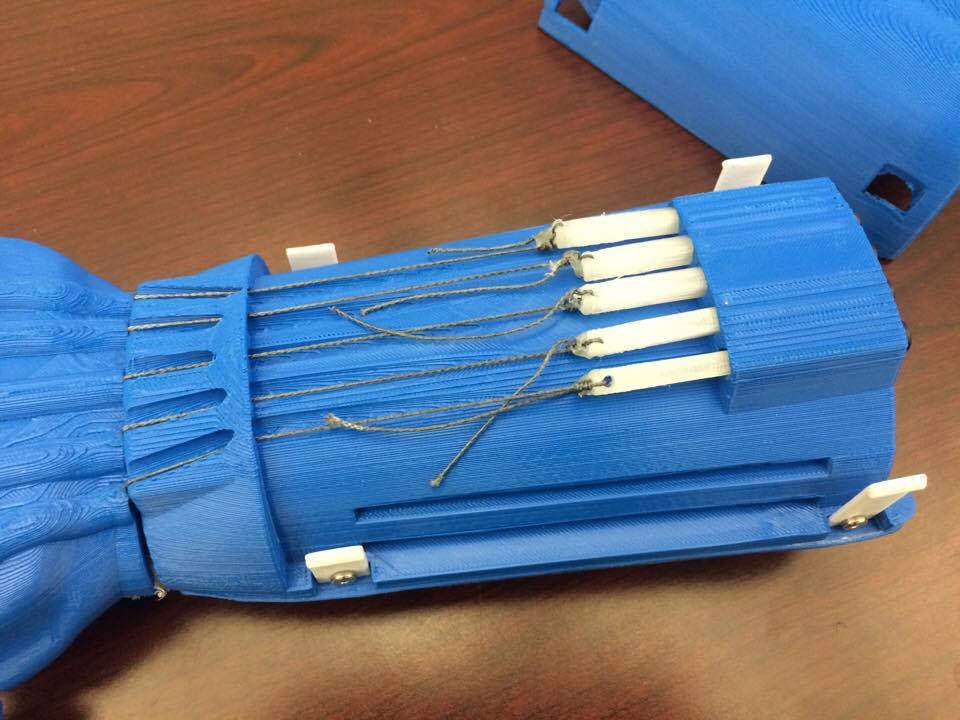

As an intern for AIO Robotics, I designed and 3D printed a prosthetic hand in collaboration with the Handling the Future club in Florida. Scalable and built to assist those with limb differences, the prosthetic hand was purely mechanical, curling the fingers via fishing line “tendons” when the wrist bent. The tendon length remained the same as the distance between the edges of the palm and forearm increased, causing the tendons to pull at the finger tips.

Streamlined Design

This prosthetic upheld a more streamlined design, maintaining the appealing amorphous curvature of the human hand. On Autodesk’s Fusion 360 CAD software, this aesthetic was achieved by lofting spline sketches on several offset planes using my own arm as a model. To create the channels, sweeps with circular profiles and paths made from sketched lines projected onto the upper surface were used.

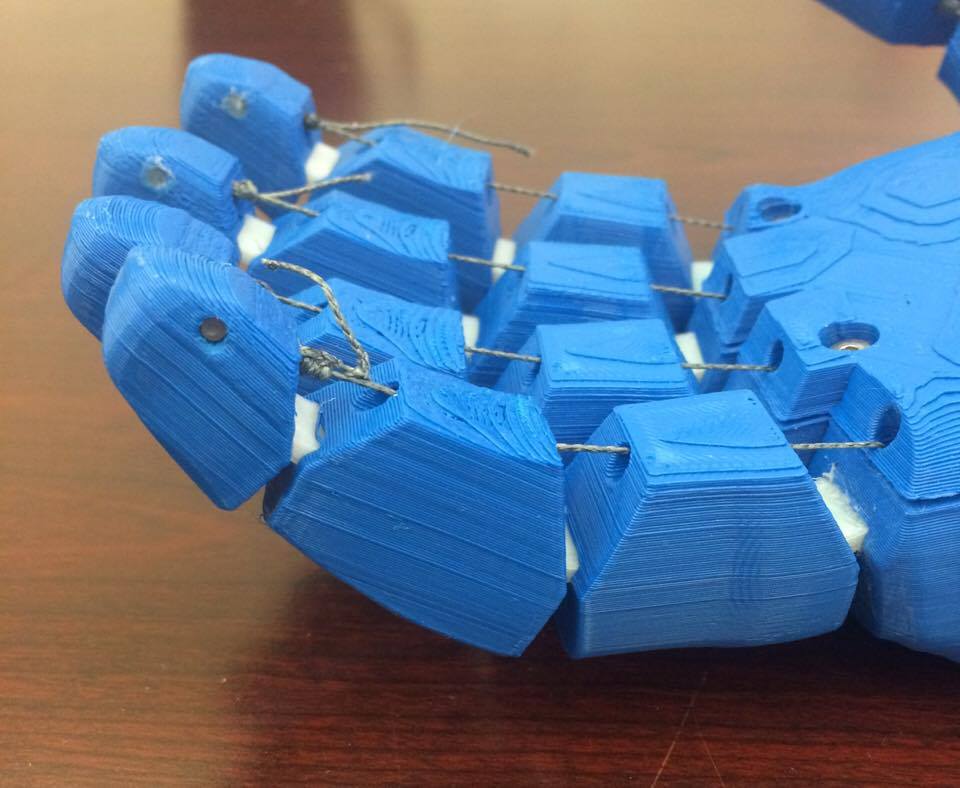

Flexible Filament Joints

The joints of the prosthetic were printed using flexible filament to preserve its functionality while allowing the prosthetic to be easily scaled.

Opposable Thumb

The thumb was designed with the tendon closer to the axis of rotation at the second hinge joint, causing the phalanx to bend first before the finger tip and hence allowing the user to clamp objects against the palm.

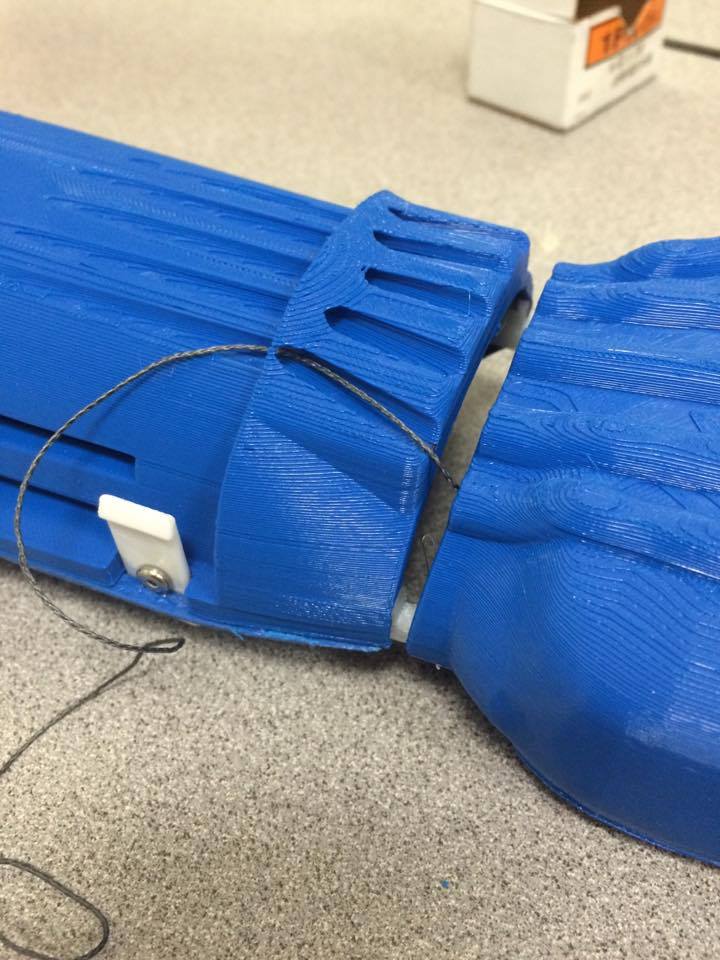

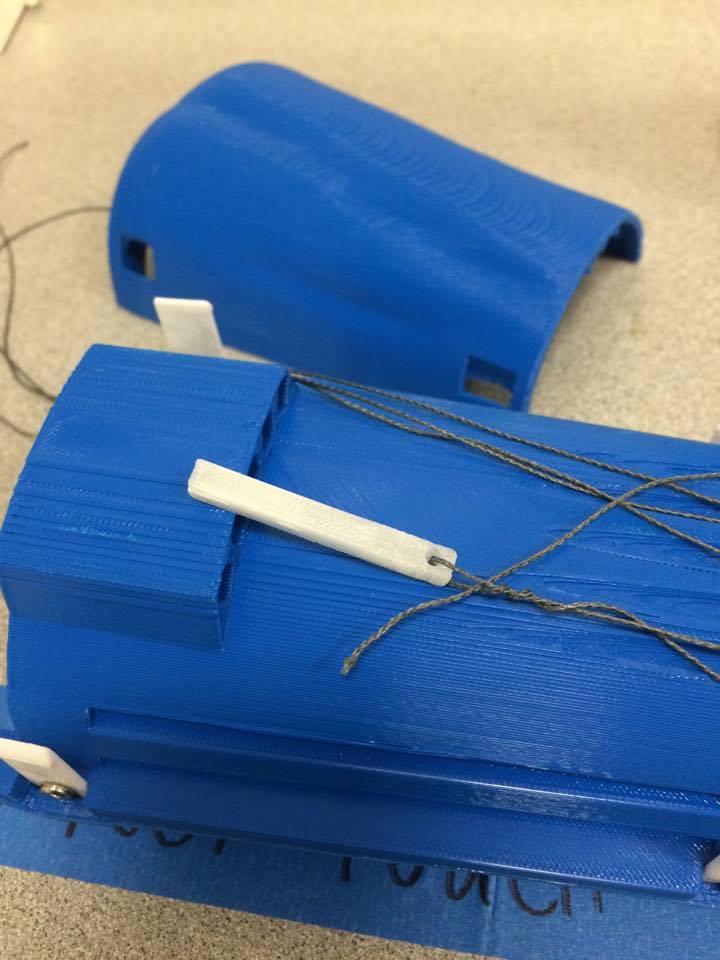

Tendon Housing and Forearm Shells

The tendons were housed in channels, preventing environmental interference and giving the prosthetic a cleaner look. Top and bottom shells clipped onto the inner forearm, concealing the tensioner pins, tendon knots, and Velcro straps for a streamlined appearance.

Tensioner Pins

Screws entered the backs of these tensioner pins. By tightening or loosening the screws, the pins pulled or relaxed the tendons, allowing the user to manipulate the tension in the strings. The mount for the pins was built into the inner forearm.

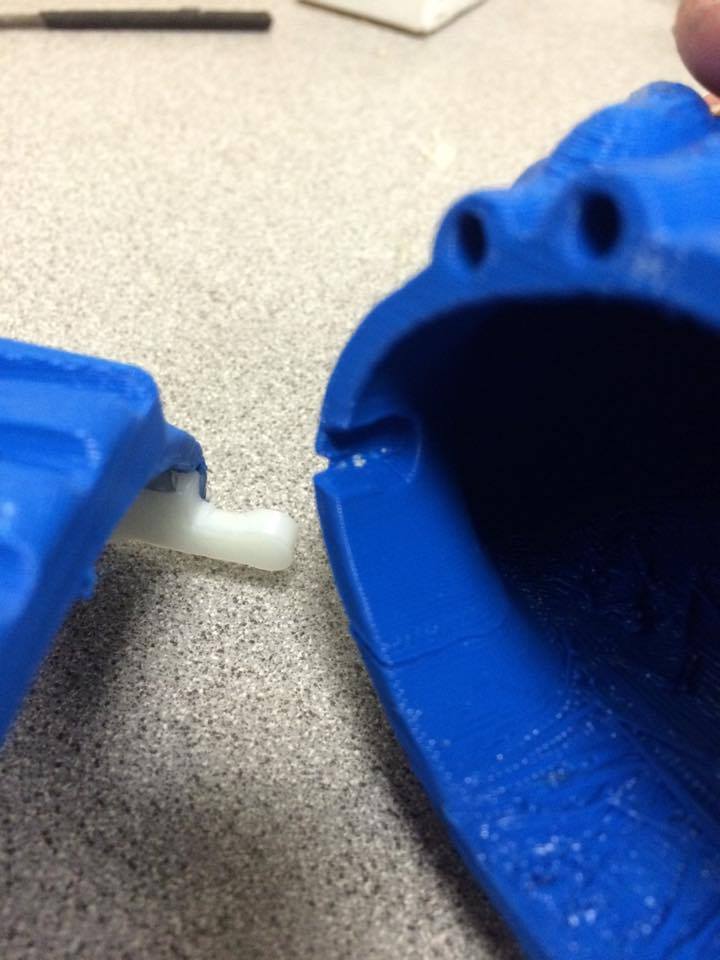

Removable Palm

A humanlike palm was screwed into upper half of the hand for easy removal. When scaling the prosthetic, scaling factors were based on these screws used to fix the palm.

Analysis of Prosthetic

CAD sketches were created when wrist was flexed to determine the approximate change in distance between the edges of the palm and forearm and thus whether the fingers would curl completely when the wrist bent. The desired distance was found by measuring the length of string pulled from a printed finger, fully curled.