Adaptive Sports Equipment and Prosthetics

Since the 2015 “Spock” Basketball Prosthetic Hand project that spearheaded 3D4E’s healthcare/prosthetics division, I’ve had a direct hand in developing several adaptive sports projects in collaboration with the Angel City Sports Facility in Los Angeles to provide more customizable, inexpensive, and accessible equipment for those who need them the most.

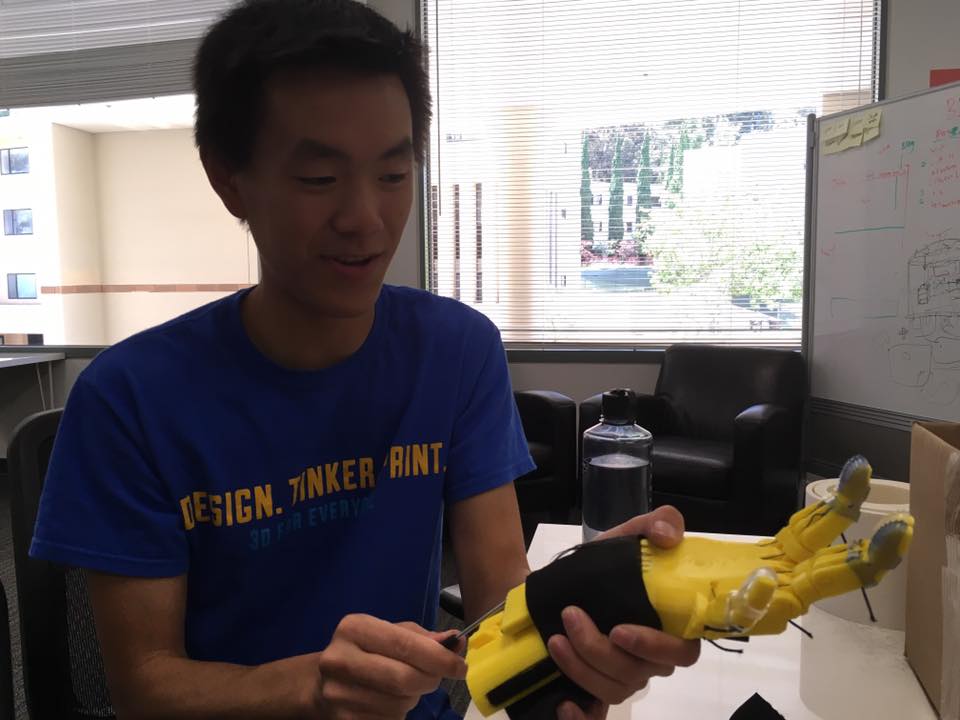

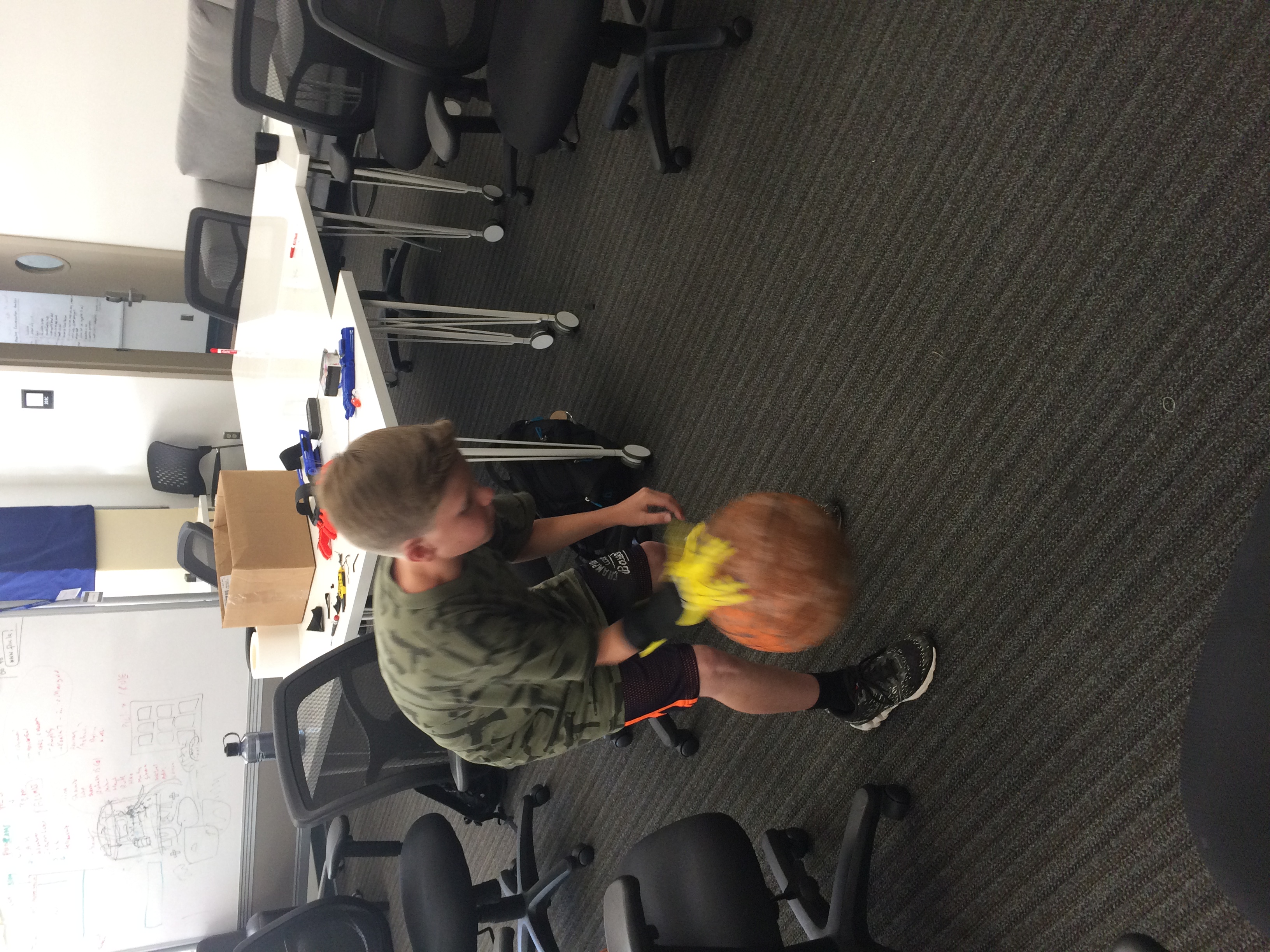

“Spock” Basketball Prosthetic Hand

Built for children with limb differences, the Spock gave them the ability to dribble, pass, and shoot a basketball. Through the organization eNabling the Future, we were able to find a youth recipient, Logan, to test and gift our prosthetic. He made 17 shots within an hour of practice. This project went on to become a finalist in the 2016 Instructables 3D Printing Contest.

Click Here for Pac-12 Video Click Here for 3D4E Video

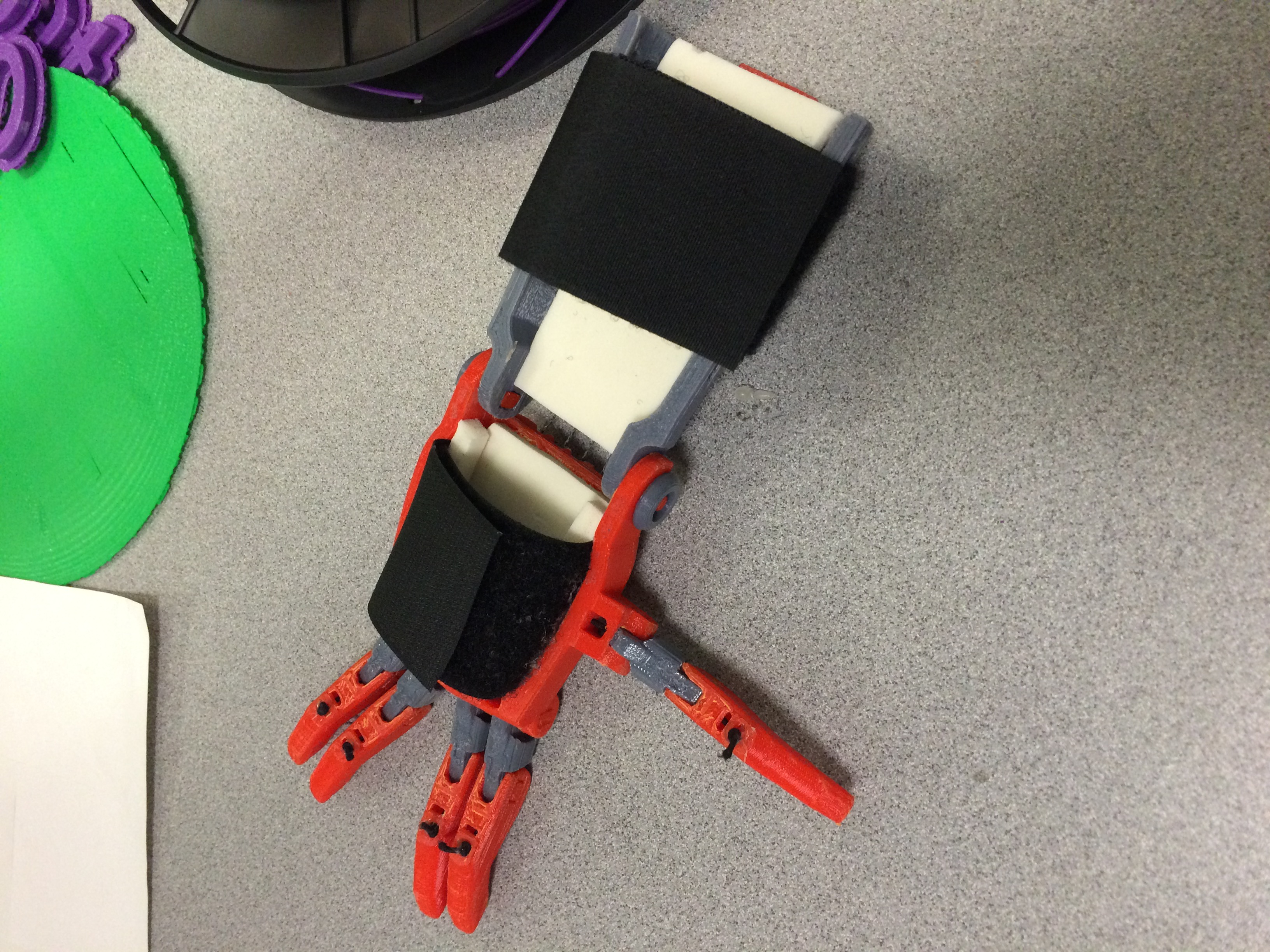

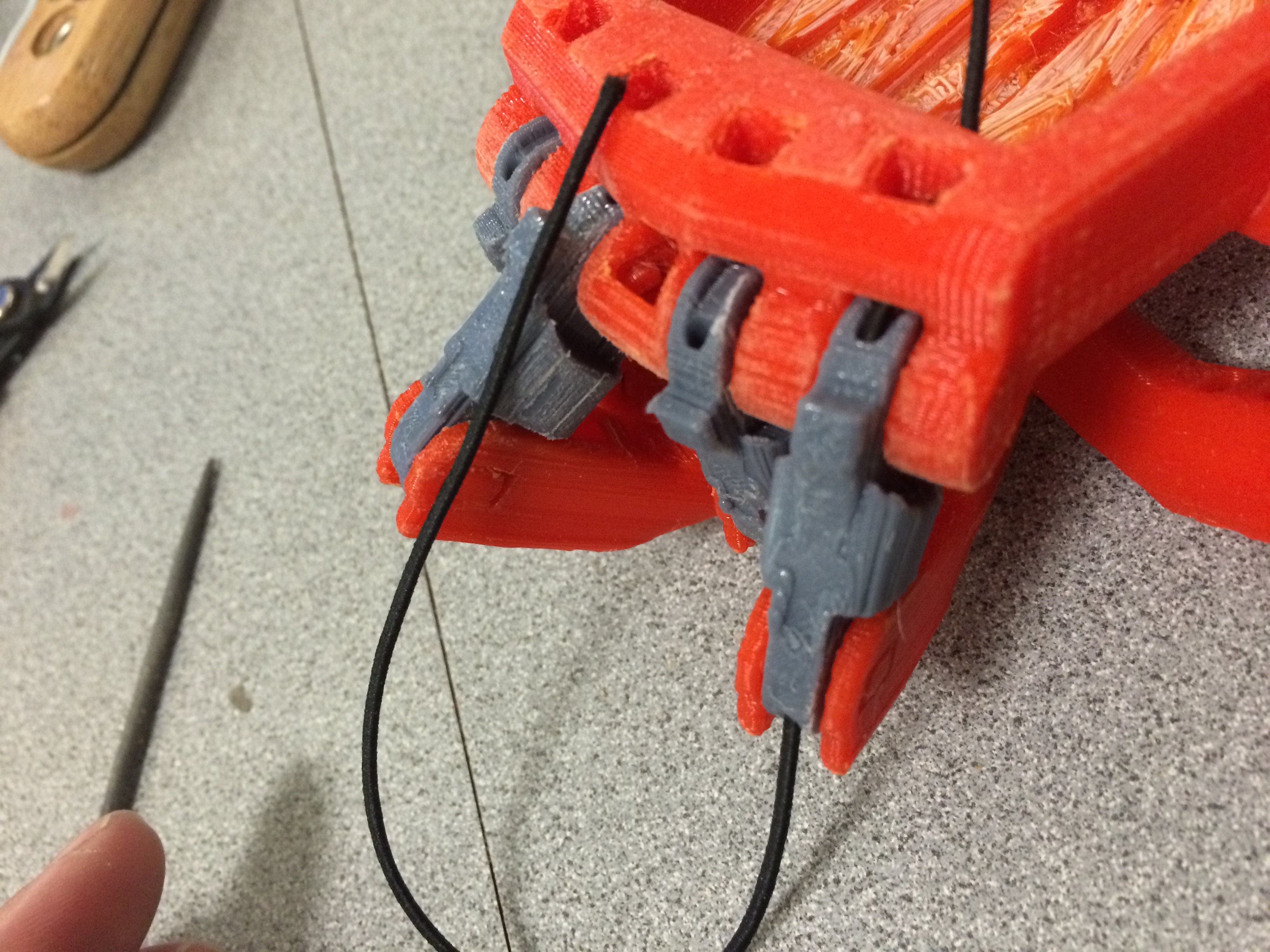

Reverse Engineering the Raptor Reloaded

I reverse engineered eNabling the Future’s Raptor Reloaded prosthetic hand so the channels guided tendons along the underside of the palm and forearm and the fingers curled when the wrist bent backwards (the “set” position of the shooting process). The fingers spread outwards when pushing the arm up and flicking the wrist forward, giving the ball upward acceleration and spin. Elastic strings running along the top side of the fingers caused the fingers to return to their original position after shooting basketballs. Adjusting the pins on the gauntlet via screws in the backs of the pins altered the tension of the tendons.

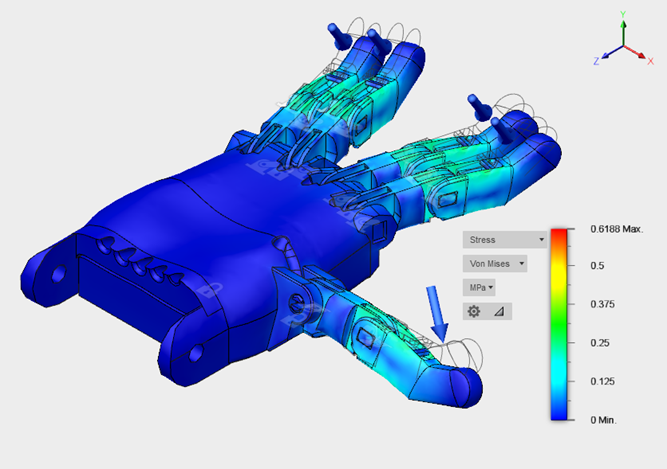

Stress Analysis of Prosthetic

The greatest stress at the joints occurred when the basketball was at the fingertips. The simulation conducted showed that the fingers did not fail under this maximum force, calculated by finding the force of gravity acting on the basketball and distributing this force across the fingertips.

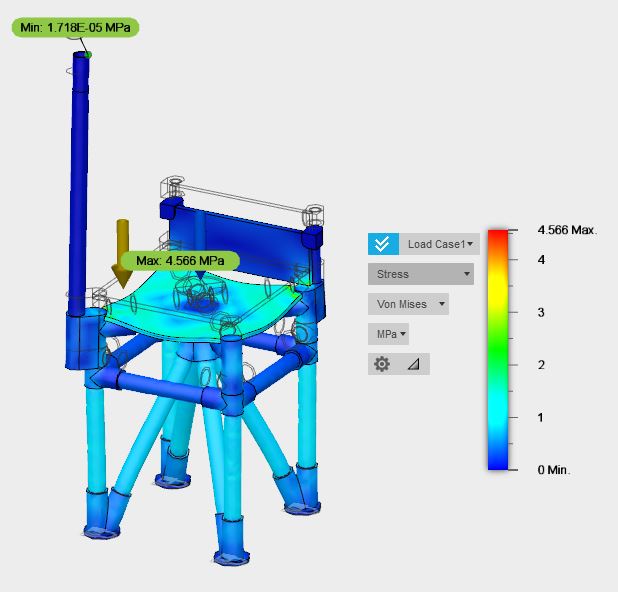

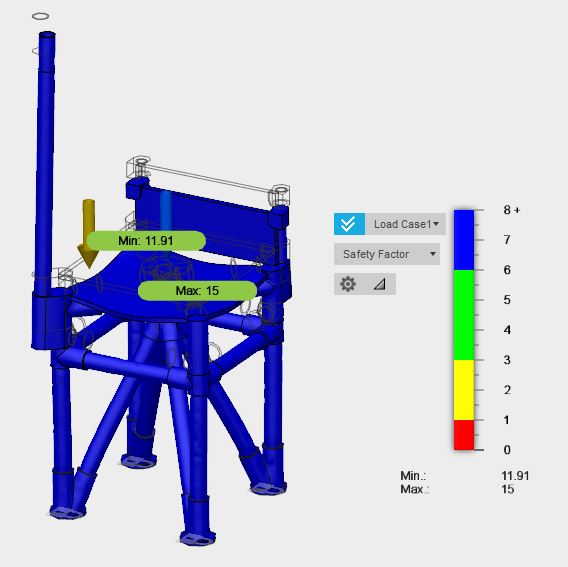

Track and Field Throwing Chair

Built for disabled shotput and discus throwers, this prototype chair was created in response to the high cost of throwing chairs that made it difficult for new athletes to get into the sport. While the joints of the chair were 3D printed, the seat was made of wood and the legs of PVC piping. The chair was held together with screws and tight press fits.

FEA simulation results on Autodesk Fusion 360 revealed that the chair with 100% infill joints could easily hold 600 pounds of force, with each joint undergoing stress much lower than the yield stress of ABS. Being able to showcase this project at Angel City Games, a major adaptive sports event held by the Angel City Sports facility, was mutually inspirational and exciting for both myself and the participants.

Wheelchair Track Racing Gloves

Designed for wheelchair track racers, these gloves are 3D printed to mold to the inside of the user’s hand so that he or she can push against the wheels of the wheelchair without injury. This project was pretty cool because it forced me to step beyond hard geometric lines and dimensions into the world of the form tool on Fusion 360.